Description

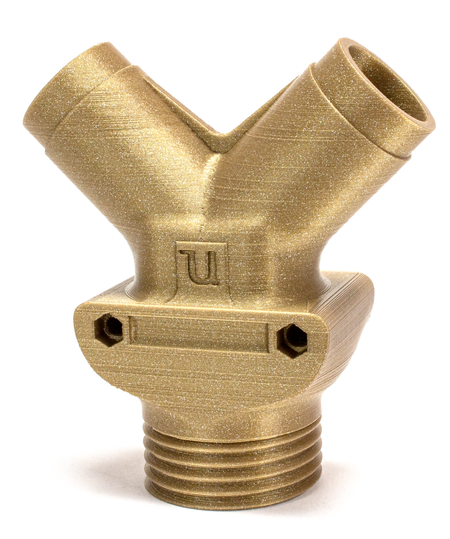

TitanX™ is a revolutionary new high-performance and FDM-optimized engineering filament. TitanX™ is the evolution of ABS into a warp-free filament extremely suitable for 3D printing large scale and high precision engineering objects. With TitanX™ we present an industrial-grade ABS-type of 3D printer filament with unsurpassed mechanical properties that is uniquely modified with FDM-optimization technology.

TitanX™ is truly FDM-optimized as it has zero warping, a perfect interlayer adhesion and can be printed directly on a heated glass plate without any adhesives or tapes to be used. This FDM-optimization combined with a perfect filament flowing behavior, thermal stability and far above average impact resistance make TitanX™ a perfect filament for 3D printing large scale engineering objects with a remarkable fine detail.

Dependent on the size and design of the printed object, TitanX™ can be printed at elevated printing speeds.

Below are displayed the unique characteristics TitanX™.

- FDM-optimized

- Excellent adhesion to heated glass plate and Kapton tape

- Warp-free

- Perfect inter-layer adhesion

- Greatly improved mechanical properties

- High impact resistance

- Great thermal stability and filament flowing behavior

- FDA food and drink contact compliant

TitanX™ has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers.

|

Filament Net Weight: |

± 0.75 Kg |

|

Spool Size (D x h): |

200 mm x 55 mm |

|

Spool Hub Diameter: |

52 mm |

|

Carton Box Size (L x W x H): |

200 mm x 200 mm x 60 mm |

|

Packaged weight |

1.25 Kg |

Printing guidelines

- Print temp: ± 240-260˚C

- Heat bed: ± 80˚C

- Print surface: Glass or Kapton tape